How to improve the overall stability through structural adjustment when the load-bearing of multi-layer storage cabinet is uneven?

Release Time : 2025-10-16

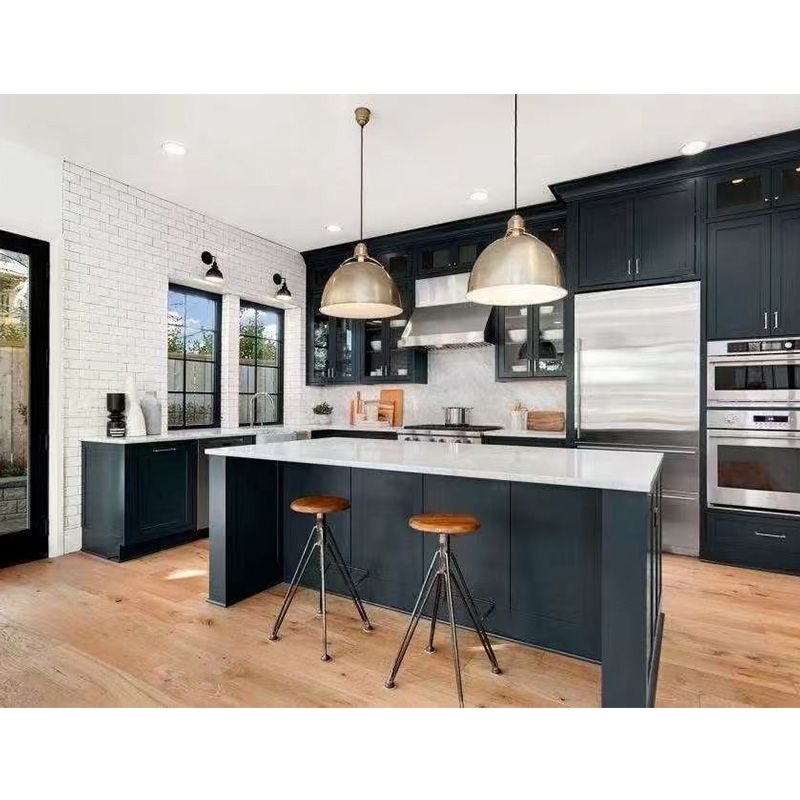

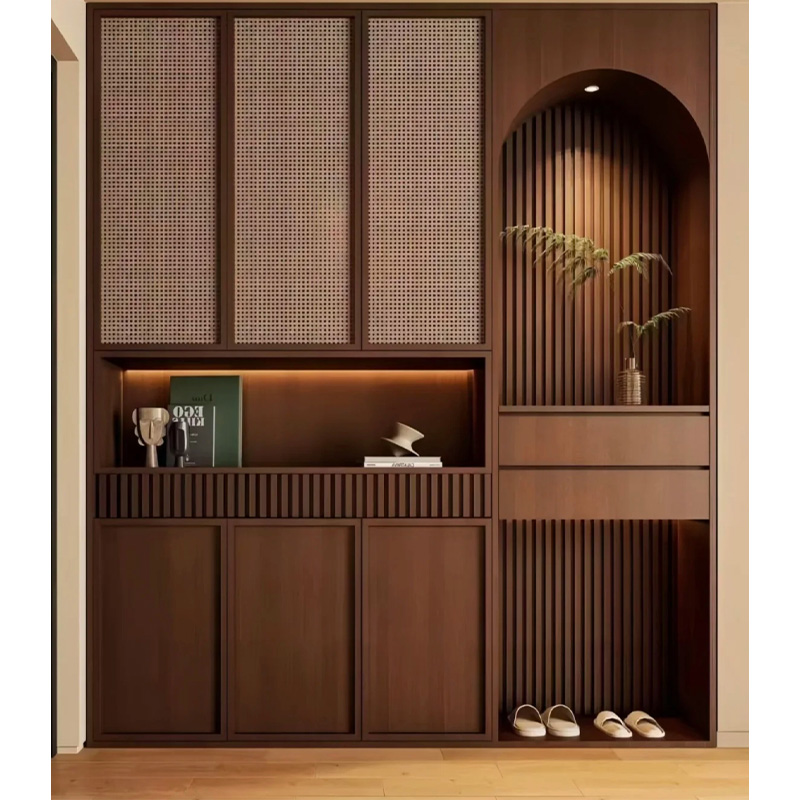

When multi-layer storage cabinets are unevenly loaded, their overall stability is affected by the material stress distribution, the strength of the connection points, and the location of the structural center of gravity. Systematic structural adjustments are necessary to achieve balanced load-bearing. When the loads on each layer of a storage cabinet vary significantly, the bottom support structure is susceptible to plastic deformation due to local overload, causing the cabinet to tilt or loosen the connections. In this case, optimizing the vertical force transmission path is a priority. For example, triangular reinforcement ribs can be added between the columns and shelves. This leverages the stability of the triangular structure to distribute vertical pressure and avoid stress concentration at a single node. Furthermore, adjusting the connection between the shelves and columns, switching from traditional point contact to surface contact, reduces pressure by increasing the contact area and minimizes local deformation caused by uneven load bearing.

The stiffness and toughness of the storage cabinet shelf material directly impacts its balanced load-bearing performance. If the shelves are insufficiently thick or the material is too soft, they can easily deform under heavy loads, resulting in a concave center and warped edges, which can cause the cabinet to wobble. Improvements include using high-density fiberboard or cold-rolled steel as the shelf base material and enhancing its bending resistance with surface embossing. For shelves with larger spans, invisible support beams can be added in the middle to distribute the shelf's load-bearing capacity to multiple points, avoiding structural failure caused by excessive stress at a single point. Furthermore, the edges of the shelves should be rolled to prevent heavy objects from impacting the cabinet side panels when they fall, indirectly improving overall stability.

The connection joints of storage cabinets are critical for load transmission. Traditional screw fastening or snap-on connections are prone to loosening due to vibration after prolonged load bearing, resulting in a decrease in the load-bearing capacity of each shelf. Improvements include adopting a mortise and tenon joint system combined with metal embedded parts. The precise fit of the tenon and groove creates a seamless connection, while the metal embedded parts enhance the tensile strength of the joints. For frequently used storage cabinets, structural adhesive can be applied to the joints to fill minor gaps and reduce stress accumulation caused by component movement. Furthermore, regular inspection and tightening of connectors to ensure optimal load bearing at all times is essential for maintaining balanced load bearing.

The center of gravity of a storage cabinet significantly impacts its overall stability. Overloading the upper shelves can cause the cabinet to tip forward, while overloading the lower shelves can cause it to tilt backward. Adjustment strategies include optimizing the distribution of floor heights, concentrating heavy items on the bottom floor and light items on the upper floors. This lowers the center of gravity to enhance tilt resistance. Furthermore, anti-tilt devices, such as adjustable support feet or wall-mounted connectors, can be added to the back of the cabinet to limit horizontal movement. For freestanding storage cabinets, bottom counterweights can be added to further balance the load-bearing differences between floors.

The side and back panels of a storage cabinet provide auxiliary support in the load-bearing system. If the side panels are insufficiently rigid, they can deform laterally when the shelves are subjected to load, causing the cabinet to twist. Improvements include adding longitudinal reinforcement ribs within the side panels to increase their moment of inertia and improve bending resistance. The back panel can be constructed of a single sheet of steel, replacing traditional corrugated cardboard. The steel's continuity distributes interlayer stress and prevents cabinet sway caused by back panel deformation. Furthermore, the joints between the side and back panels should be welded or riveted to ensure continuous force transmission and prevent load imbalance caused by loose connections.

The bottom structure of a storage cabinet is the ultimate load-bearing point. An uneven floor or improperly adjusted feet can lead to uneven load distribution across the floors. Adjustment measures include using adjustable feet that can be rotated to ensure full floor contact and eliminate any overhang caused by uneven ground. For heavy storage cabinets, horizontal tie rods can be added to the bottom to connect multiple cabinets into a single structure, distributing the load pressure of individual cabinets through collective stability. Furthermore, the bottom frame should adopt a closed-loop structure to avoid the interruption of force transmission caused by an open design and ensure that the load is evenly transferred to the floor.

Through a combination of measures such as upgraded materials, optimized connections, center of gravity adjustment, and bottom reinforcement, multi-layer storage cabinets can achieve both balanced load-bearing and improved overall stability. Actual adjustments should be tailored to the storage cabinet's usage scenarios and load characteristics, with targeted optimization of key structural nodes to avoid stress imbalances in other areas caused by single component modifications. Finally, the storage cabinet should be verified through static load testing to ensure that it maintains both vertical and horizontal stability under maximum load.